Day 6 - A little bit of the ol' DIY: A passive mult

The humble 2hp passive mult.

A quick disclaimer before we go into the cool stuff: have no idea what I'm doing, and as such I cannot be held responsible for any damage you inflict upon yourself or your valuable synthesizer equipment as the result of having attempted the project below. I am not an expert at anything, I swear, so your reckless willing to follow in the footsteps of an idiot like me is your own freaking fault. I totally recommend you don't do it.

So with that out of the way, I'd like to present you with a badass DIY project idea that's totally cool and so incredibly easy that even an idiot like me can do it.

You probably already know what a mult is, right? It's sort of like a module that acts the same way a stack cable does, duplicating a signal across multiple connections in your patch. Most n00bs like me probably don't need anything more fancy than a plain-Jane passive mult most of the time... I'm not even yet sure what the advantages of a buffered mult are, besides maybe avoiding the inevitable slight voltage drop you'll see in passive mults have. Regardless, a passive mult is pretty useful to me, and crazy easy to build. Livestock Electronics provided an excellent tutorial on Instructables.com, and it seemed legit, so I thought I'd give it a try. I have one sort of cool advantage in that I have a 3D printer, so I don't need to spend hours patiently scoring acrylic and sanding down its jagged edges. Or at least that was my hope.

I fired up OpenSCAD and whipped up a pretty decent parametric .SCAD file that creates Eurorack panels. Maybe you guys know of a better .SCAD for this purpose, but I could not find one. With a blank 2hp panel at hand, I created another model with 8 ~6mm holes for mounting 3.5mm sockets (such as these) and was off to the races. The print took only 15 minutes and seemed to turn out nicely. I regret having used a more flexible fake-wood PLA, as these panels truly need to be a bit more rigid than this material allows, but whatever. In hindsight, T-Glase might have been a better choice.

You can see a fair amount of warping as the result of having pulled the print off the print bed before it was completely cool. Once I popped it in the case, it was pretty straight.

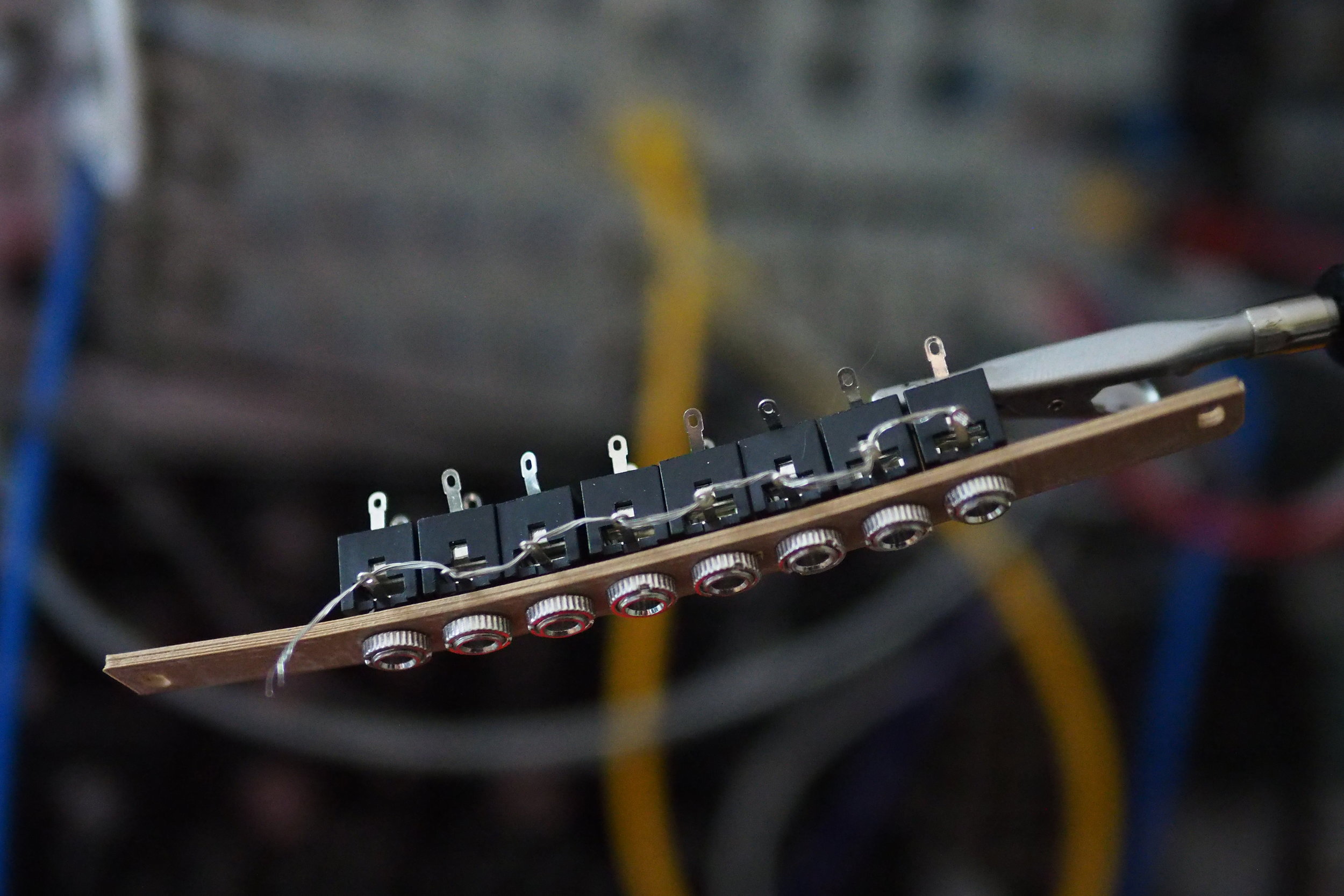

After affixing the 3.5mm jacks and attaching their nuts, I threaded a conductive wire through the eyelets, connecting each ground to ground and each positive to positive, soldering them in place, and Bob's your uncle. Including the time it took me to code the .SCAD file, the whole project took just a couple of hours. Better still, the total cost of the project is roughly $5.00, unless you count the $1500 3D printer, but if you're into modular synths, that's chump change. To join in the fun, check out the models on Thingiverse and, again, please consult a professional before you negligently damage your equipment.